I'm so desperate to get rid of the ______ _____ _____ popping!! I've checked, rechecked, and triple checked just about everything but I'm still running lean! I'm at my wits end and almost ready to give up, but I refuse to let this beat me. I will try anything and will probably retry everything. Your suggestions and support are most welcome.

For those of you who have been following my thread, http://www.hondashadow.net/forum/72-technical-discussion/107170-air-filters-lean-mixture.html, this is a continuation of that thread.

A quick recap of the problem/symptoms:

This has actually been a problem for at least a year now. Some of you may remember my thread, http://www.hondashadow.net/forum/72...echnical-discussion/94574-new-rider-old-bike-soon-ether-junkie-choke-cable.html. The choke cable was crimped causing the choke valve to rust open. In addition, or maybe related, my gas tanks were completely rusted. Needless to say the carbs and engine were flooded with rusty gas. This is how I unknowingly bought the bike. When I replaced the choke cable and was finally able to close the enrichment circuit, the bike has run lean ever since.

A quick recap of tests and attempted solutions:

Thank you in advance for everyone's input no matter how big or how small. I'll try anything!!

For those of you who have been following my thread, http://www.hondashadow.net/forum/72-technical-discussion/107170-air-filters-lean-mixture.html, this is a continuation of that thread.

A quick recap of the problem/symptoms:

- Major popcorn sounds on deceleration or when the throttle is closed while the engine is revving at high RPMs

- Lack of power for first quarter throttle

- White spark plugs after driving around below first quarter throttle. Almost tan plugs after driving on the highway

- Low 30s mpg when driving around town but 50+ mpg on the highway.

- Engine revs +2-3000 rpms when a paper towel is stuffed into air box. Adjusting idle screw to 1000 rpms produces a beautiful idling sound with very responsive throttle and no popping. However, the engine will die if driven around past 1/4 throttle...

This has actually been a problem for at least a year now. Some of you may remember my thread, http://www.hondashadow.net/forum/72...echnical-discussion/94574-new-rider-old-bike-soon-ether-junkie-choke-cable.html. The choke cable was crimped causing the choke valve to rust open. In addition, or maybe related, my gas tanks were completely rusted. Needless to say the carbs and engine were flooded with rusty gas. This is how I unknowingly bought the bike. When I replaced the choke cable and was finally able to close the enrichment circuit, the bike has run lean ever since.

A quick recap of tests and attempted solutions:

- Acid etched both gas tanks and lined with POR15 to remove and prevent rusting

- Replaced all fuel lines and gas filter (Auto zone brand/not OEM)

- Rebuilt Carbs: Completely disassembled carbs and dipped into Berryman's Chem dip for at least 24 hours - each carb separately. Cleaned varnish and rust particulate with metal brushes and guitar wire. Sprayed all ports with compressed air in a can. Replaced all o rings and gaskets with Honda gasket kit. (Pilot screws were left in carbs for cleaning because one couldn't be removed at first, http://www.hondashadow.net/forum/72-technical-discussion/95160-pilot-screws-jet-needles.html. Past owner was a real jerk apparently)

- Second Carb cleaning: professionally tapped out broken pilot screw and redipped in chem dip. Returned float level and pilot screws to factory settings.

- Built manometer and synced carbs

- Adjust screws to +1 from factory setting (~4 turns)

- Replaced Spark plugs and gapped to spec

- Tested all plugs for spark

- Added Berryman's B12 over 3 gas tanks

- Tested for air leaks with can of ether and repaired: Found some minor leaks around rubber boots above carbs and the airbox. Removed rubber boots from air connecting tube (a.k.a. the snorkel). It was very dirty with failing sealant. It was unknown if the the sealant was from past owner or factory. Cleaned away and replaced with only a little bit of oil. No one seemed to know if sealant was necessary in the thread: http://www.hondashadow.net/forum/72-technical-discussion/108397-rubber-boots-sealant.html. Also cleaned similar grime/oil/dirt/sealant from elbow and rubber boot where the crank case breather hose passes through air box. Also found same stuff on rubber boot where air connecting tube meets the air box. No sign of air leaks after cleaning when testing with a can of ether at idle. Still wondering if the sealant is necessary to prevent leaks at higher rpms.

- Replaced copper gasket at exhaust port and tightened to spec torque

- Cleaned OEM air filter and reoiled using 90wt gear oil as per shop manual

- Replaced air filter with UNI foam filter and oiled with uni foam oil

- Replaced spark plugs once again. (Broke one and decided to replace them all: http://www.hondashadow.net/forum/72-technical-discussion/107215-reusing-used-spark-plugs.html)

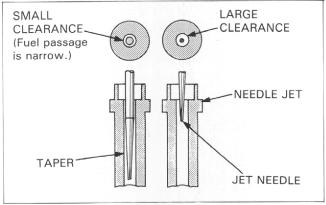

- Cleaned carbs for third time: Removed carbs and all jets, needles, plugs, screws and diaphragms but left carbs connected (synced). Dipped in 80/20 pine sol/water for two days. Checked every 12 hours or so to spray all circuits from all ends with 80 psi of air and then sprayed with acetone. No real signs of varnish or clogs (good spray of acetone from exit points). Passed guitar string where possible. Rinsed with hot water before returned to pin sol bath. Repeated 3 or 4 times. Polished jet needle (which was pretty worn on one side) with brasso until smooth. Polished float seats with brasso. Rebuilt carbs and returned float level and pilot screws to factory settings.

- Checked for leaks with can of ether

- +1 turn of pilot screws from factory settings (~4 turns total)

- Checked fuel pump flow rate: 117 cc in 13 seconds (~540 cc per minute) Spec is 614 cc per min +/- 10%... which puts me right on the low end

- Readjusted raised float levels to be rich (adjusted from 7.5mm spec to 6.5mm)

- Lightly sanded plastic carb slide with 1000+ grit paper (I dunno... getting desperate)

- Rechecked for leaks with ether

- Replaced stock 40 pilot jets with size 42s

- Rechecked for leaks with ether

- 1/3 can of Berryman's b12 in 2.5 gallons of gas in fuel tank.

Thank you in advance for everyone's input no matter how big or how small. I'll try anything!!